CANCEL

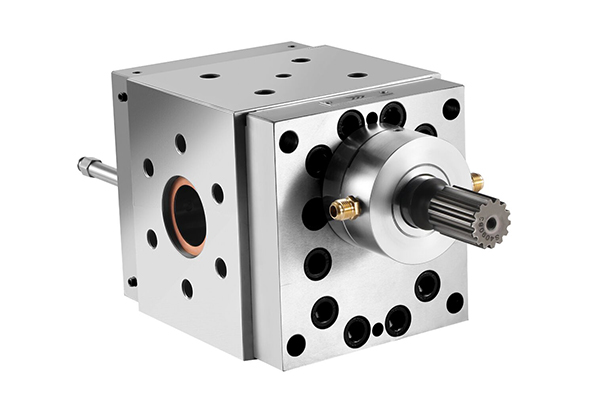

The pump body of high-temperature melt pumps adopts integral hardening technology and is made of high-temperature alloy steel materials with high wear resistance and corrosion resistance. Compared to ordinary extrusion pumps, they are more suitable for high-temperature and high-pressure working conditions, meeting the performance requirements of some users. High-temperature melt pumps are based on standard series melt pumps, with enhanced design parameters for the pump body, such as high torque, low shear requirements, and high corrosion resistance requirements (including fluorine-containing products).

Optimized designs have been implemented for the self-lubrication system, inlet and outlet flow channels, and gear structure of the pump body in high-temperature melt gear pumps. These designs reduce the residence time of materials within the pump body, prevent dead zones in the pump gears, and make them more suitable for extruding products with high smoothness and transparency requirements, such as PC, PMMA, and PVC, as well as heat-sensitive materials.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Material selection of melt pump

What materials can the melt pump transport?

Application areas of plastic extrusion melt pumps

Heiko Company had participated in the CHINAPLAS 2024.

High-temperature melt gear pump in the chemical fiber spinning applications

Extruders with screen changers: cost-saving for stable production

How can melt-pumps help extrusion line to reduce costs and increase efficiency?

Which extrusion lines are screen changers used in?

Plastic extruder screen changer: standard and customized full analysis

TPU pelletizing melt-pump