CANCEL

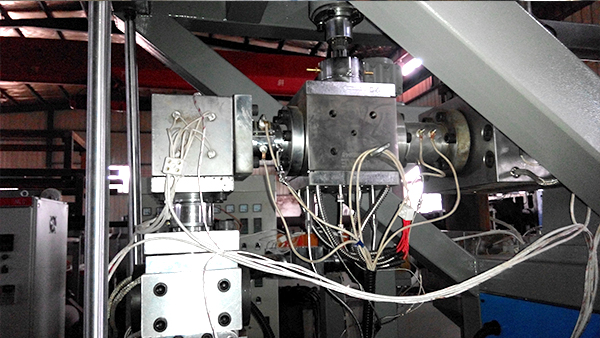

Extruder metering pumps play a pivotal role in the extrusion molding process, with their primary functions and advantages summarized as follows:

I. Primary Functions

Stabilizing Output Pressure: Extruder metering pumps effectively mitigate material output instability and pressure pulsations caused by extruder parameters, ensuring the stability of the extrusion process. By stabilizing pressure output, they minimize dimensional tolerances in extruded products, reducing waste and reject rates.

Enhancing Product Quality: Melt metering pumps precisely regulate melt flow rates and pressures, ensuring dimensional accuracy and surface quality of extruded products. They eliminate feeding errors in the charging system, dampen fluctuations transmitted from upstream processes, and enable rapid entry into a stable operating state.

Boosting Extrusion Output: By reducing pressure requirements on the screw, metering pumps enhance extrusion throughput. They build pressure toward the die, allowing high-speed screw extrusion while minimizing melt residence time in the barrel, stabilizing the plastication process, and lowering melt temperatures, thereby increasing both product yield and quality.

II. Advantages

Energy Efficiency: By shifting the pressure-reduction function of the extruder to the metering pump, extruders can operate at lower pressures and temperatures, reducing energy consumption. Through optimized design and precise control, metering pumps significantly enhance production efficiency.

Prolonging Machine Lifespan: Melt metering pumps reduce extruder backpressure, minimizing wear between the screw and barrel, thereby extending machine lifespan. They also alleviate loads on gearbox thrust bearings, enhancing overall equipment reliability.

Facilitating Monitoring and Control: Melt metering pumps exhibit linear extrusion characteristics, facilitating coordination between upstream and downstream equipment. By collecting pressure and temperature data at the inlet and outlet of the melt metering pump, they enable full online monitoring and feedback control of the entire extrusion process.

Versatility: Melt metering pumps are suitable for a variety of melt materials, meeting the needs of different industries. They find widespread applications in plastics, rubber, chemical fibers, and chemicals, among others.

Easy Maintenance: The rational structural design of melt metering pumps facilitates easy maintenance and servicing, reducing downtime and maintenance costs, and improving equipment utilization rates.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Material selection of melt pump

What materials can the melt pump transport?

Application areas of plastic extrusion melt pumps

Heiko Company had participated in the CHINAPLAS 2024.

High-temperature melt gear pump in the chemical fiber spinning applications

Extruders with screen changers: cost-saving for stable production

How can melt-pumps help extrusion line to reduce costs and increase efficiency?

Which extrusion lines are screen changers used in?

Plastic extruder screen changer: standard and customized full analysis

TPU pelletizing melt-pump