CANCEL

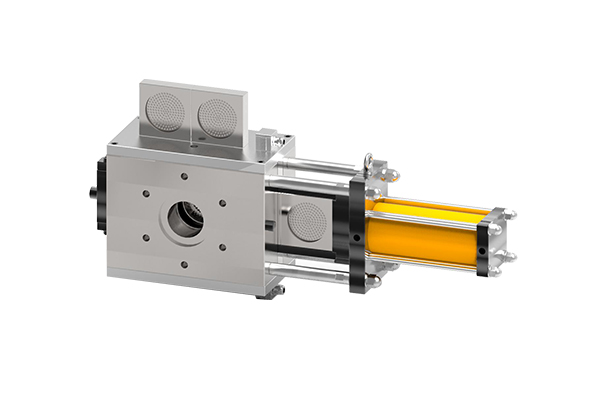

Plate hydraulic quick screen changer is mainly used in the production of thermoplastics, including sheet, plate, pipe, profile, blown film, cable, Pelletizing, rubber and other fields.

1, the normal filtration stage: in the production process, the melt or fluid medium through the inlet of the single-plate screen changer into the flow through the working state of the filtering station on the filter mesh. Filter net intercepts and removes impurities and particles in the fluid to ensure the purity and quality of the fluid. The filtered fluid flows out through the outlet of the screen changer into the next process or device.

2, change the net operation stage: when the work station on the filter due to excessive accumulation of impurities and affect the filtering effect, the need to change the net operation. The operator starts the hydraulic device through the electrical control system, and the hydraulic device drives the slide plate to move rapidly. In a very short period of time, the slide plate will push out the dirty mesh station from the main body of the mesh changer, and at the same time, the standby station enters the working position, completing the switching of stations. During the switching process, since the standby station has been pre-installed with new filter mesh, it can immediately take over the working station to continue the filtering operation, realizing the continuity of production.

The structure of plate-type hydraulic quick screen changer consists of basic parts such as screen changer body, slide plate, hydraulic cylinder, insulation plate, etc.; it adopts pressure-driven rigid sealing technology, which prevents leakage and prolongs the service life, and the sealing gap can be automatically compensated with the use process. It can meet the high extrusion volume production of any polymer, and can be used with different standard extruders without stopping to change the screen and without leakage.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Material selection of melt pump

What materials can the melt pump transport?

Application areas of plastic extrusion melt pumps

Heiko Company had participated in the CHINAPLAS 2024.

High-temperature melt gear pump in the chemical fiber spinning applications

Extruders with screen changers: cost-saving for stable production

How can melt-pumps help extrusion line to reduce costs and increase efficiency?

Which extrusion lines are screen changers used in?

Plastic extruder screen changer: standard and customized full analysis

TPU pelletizing melt-pump