CANCEL

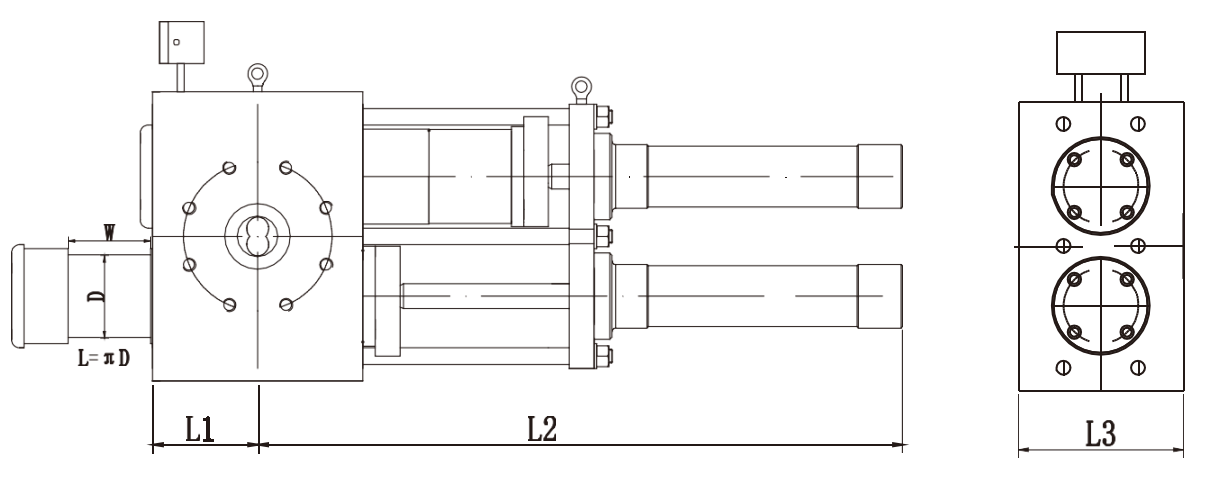

The screen changer is designed with a double-column filter cartridge structure, with a large filtration area, which reduces the frequency of screen change, improves the interval time of screen change, and can realize non-stop screen changer.

The screen changer is designed as a double-column filter cartridge structure, with a large filtration area, reducing the frequency of screen changing, improving the interval time of screen changing, and can realize non-stop screen changer, and is designed with a material introduction and exhaust device, which can fully exclude the gas in the material, and can completely solve the problem of bubbles when changing the screen, ensure the quality of the product, and improve the stability of the product.

Performance characteristics:

The large filtration area is suitable for extrusion lines with higher output and dirtier materials.

No interruption of material flow, no interruption of products, to achieve non-stop network change operation.

It is suitable for continuous operation of high-capacity, high-efficiency and large-scale extrusion equipment.

The structure design is reasonable and the operation is convenient.

Applications:

The double-column large filter cartridge screen changer is suitable for dirty materials, especially waste with high impurity content, such as PP, PE, PS, PA, AB and other waste granulation conditions, and high filtration precision, large production flow, good stability, high degree of automation on medium and large production lines.

| type | Filter size | Output | Heater | |

| (mm*mm) | (kg/h) | Voltage(V) | Heating Power (KW) | |

| HK-DP-2L-500 | 298x85x2 | 200 - 1000 | 220V/380V | 6 |

| HK-DP-2L-1200 | 424x130x2 | 300 - 2000 | 220V/380V | 8 |

| HK-DP-2L-1600 | 471x170x2 | 400 - 3000 | 220V/380V | 10 |

| HK-DP-2L-2000 | 533x190x2 | 400 - 4000 | 220V/380V | 12 |

| HK-DP-2L-3000 | 644x225x2 | 500 - 5000 | 220V/380V | 13 |

| HK-DP-2L-4200 | 722x290x2 | 500 - 6000 | 220V/380V | 14 |

| HK-DP-2L-5200 | 533x500x2 | 600 - 7000 | 220V/380V | 16 |

Note: The actual output depends on material fowability, fiter fineness and materal purity. Specications are subject to change without pror notice

Melt pumps have the advantages of compact structure, simple manufacturing process, low cost, and insensitivity to oil contamination, and are widely used. However, due to defects or improper maintenance in manufacturing, assembly, operation, and maintenance, the pump will often be damaged prematurely......

The melt metering pump is mainly installed at the outlet of the extruder for metering and pressurizing various melts. The advantages of the melt metering pump are safe and reliable operation, stable performance, long service life and low operating costs. The extruder melt metering pump is a positive......

Theoretical displacement of melt pumpThe volume of melt discharged per revolution is called the theoretical displacement of the melt pump, or pump displacement, and its unit is cc/r or cm³/r. The specifications of melt pumps are generally expressed in terms of displacement.Theoretical flow rate of m......

If you have any questions or concerns, you can contact us by leaving a message.