CANCEL

Pump characteristics:

1. Good temperature adaptability: (-50~350)°C

2 Greater inlet vacuum: (-0.05~-0.09 MPa

3. High outlet pressure range: (0~40) MPa

4. Can be adapted to materials with different viscosities: (0.0003~40,000) Pa·s

5. Accurate measurement: multi-head spinning output, uniform wire diameter and thickness

6. Various heating methods: fully jacketed heating (suitable for liquid phase or vapor phase heat medium heating); electric heating (convenient and fast)

7. Stable flow: high manufacturing precision, small flow pulsation, and variable frequency motors can also be used for fine-tuning and precise control.

8. Excellent materials, corrosion-resistant, reasonable and reliable structure, durable and stable

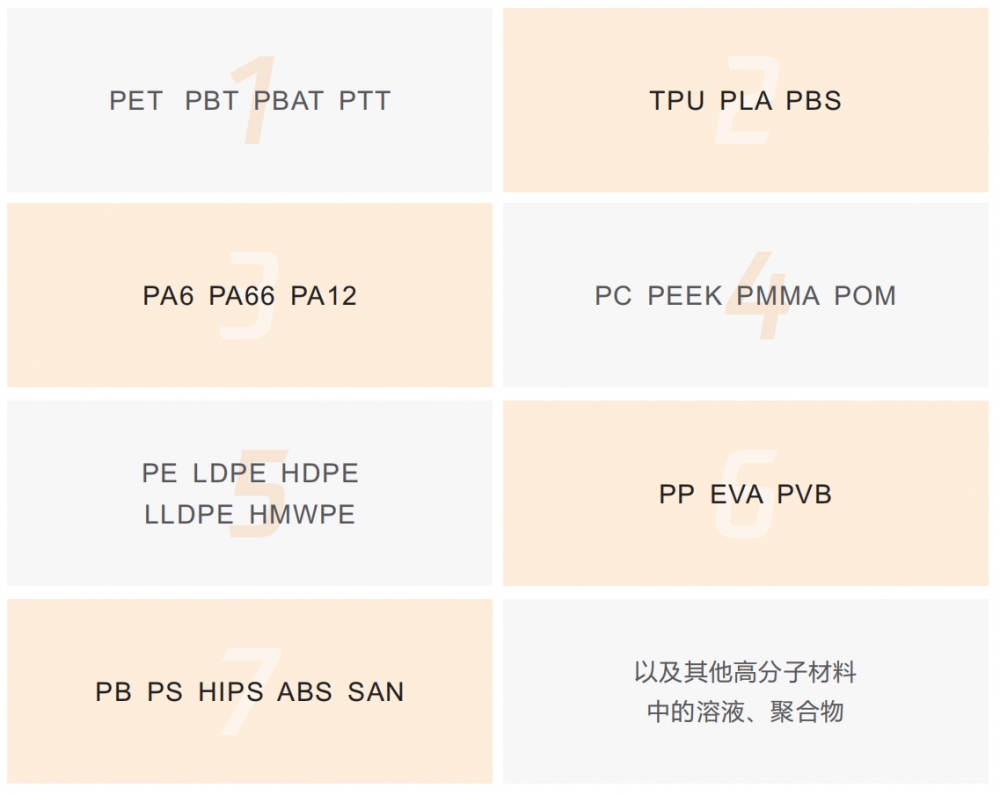

Materials that can be conveyed:

Melt pump common faults and countermeasures

Functions and advantages of the hydraulic pelletising screen changer

Screen changer leakage phenomenon of different working conditions solutions

Melt Thermal Degradation in Relation to Melt Pump Structure

Melt booster pump jamming and end cap leakage

Features and technical advantages of melt-pumps for heat-sensitive materials

Overview of Hydraulic Screen Changer Technology

Structure and working principle of high temperature melt-pump

How do you change the screen on an automatic screen changer?

What factors does consider, choosing hydraulic screenchanger of PVC pelletizing