CANCEL

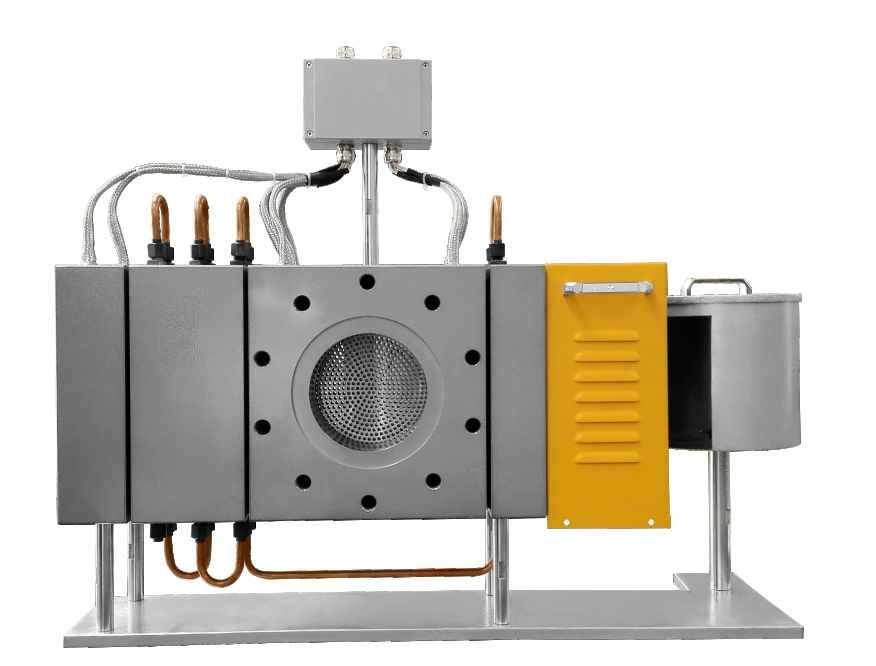

When the automatic screen changer's roll of filters are used up, we need to stop the machine to replace a new roll of screen. The specific steps for replacing the screen are as follows.

1, shut down the extruder.

2, turn off the cooling water, disconnect the plastic water pipe in and out of the water.

3, set the screen temperature to the melting temperature of the plastic, set the filter time to zero; this time, the screen heating tube began to continuously heat until the set temperature. (Note that each time after setting the time away from the network, you need to re-operate the time away from the network switch, in order to make the settings take effect. That is, turn off and on once);;.

4, to be out of the net mouth and cooling section of the plastic completely melted, usually takes 30 minutes, with the appropriate tools to simply clean out the cooling section and walk the net section of the molten material, and then pull out the screen with force;

5、Use suitable tools to clean up the material inside the screen inlet plate, screen outlet plate and cooling section of the automatic screen changer.

6、Put a brand new roll of filter mesh into the mesh belt box of the automatic screen changer.

7、Pass the filter through the screen inlet plate completely through the screen changer.

8、Adjust the screen temperature and filtering time to the value set in normal production.

9, connected to the inlet pipe, open the water inlet valve, this step should be noted that the water will be out of the high pressure water vapor spray, should ensure that there are people at the scene near the outlet, to prevent scalding.

10, to confirm that no steam sprayed out of the outlet and the water flow is stable, connect the outlet pipe.

11, out of the mesh plate temperature drops to the normal production temperature, that is, automatic screen changer mesh belt replacement is complete.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.

Melt pump common faults and countermeasures

Functions and advantages of the hydraulic pelletising screen changer

Screen changer leakage phenomenon of different working conditions solutions

Melt Thermal Degradation in Relation to Melt Pump Structure

Melt booster pump jamming and end cap leakage

Features and technical advantages of melt-pumps for heat-sensitive materials

Overview of Hydraulic Screen Changer Technology

Structure and working principle of high temperature melt-pump

How do you change the screen on an automatic screen changer?

What factors does consider, choosing hydraulic screenchanger of PVC pelletizing