CANCEL

Pelletizing industry has modified granulation, recycling granulation, masterbatch granulation, reactor material, etc., modified granulation and masterbatch granulation using plate, column type screen changer, recycling granulation using no net slag filter. For soft PVC granulation, because the raw material is easy to aging, in the selection of hydraulic screen changer, need to consider the following aspects.

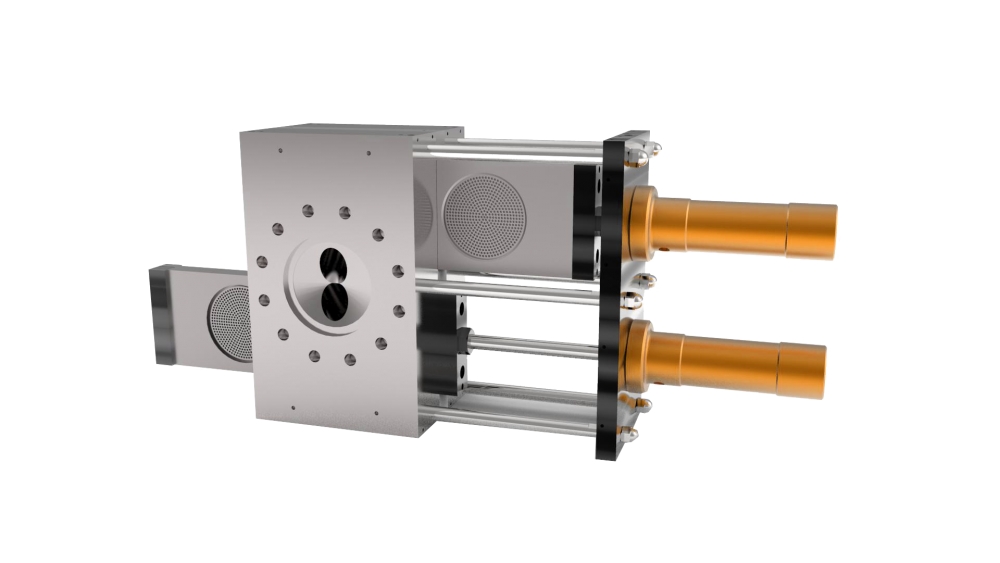

Soft PVC and other easy to aging raw materials for granulation, to choose the flow channel straight, no dead ends, no stagnant flow of hydraulic screen changer, and double-plate duplex hydraulic screen changer is very suitable for a screen changer, but also at present the only hydraulic screen changer can be used. So similar to the production of soft PVC and other easy to aging raw materials, double-plate duplex hydraulic screen changer in the original basic structural transformation and upgrading, and the use of different processing technology to achieve the corresponding production requirements.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.

Melt pump common faults and countermeasures

Functions and advantages of the hydraulic pelletising screen changer

Screen changer leakage phenomenon of different working conditions solutions

Melt Thermal Degradation in Relation to Melt Pump Structure

Melt booster pump jamming and end cap leakage

Features and technical advantages of melt-pumps for heat-sensitive materials

Overview of Hydraulic Screen Changer Technology

Structure and working principle of high temperature melt-pump

How do you change the screen on an automatic screen changer?

What factors does consider, choosing hydraulic screenchanger of PVC pelletizing