CANCEL

The combination of gear pumps and screen changers can bring many positive benefits to a new blown film line or to the retrofit of an existing line.

Three key benefits of adding a gear pump to your extrusion line:

1. reduces extruder head pressure fluctuations

2. Increase throughput

3. Reduces melt temperature (reduced residence time = lower temperature = higher rate)

Other benefits:

1. Reduced wear and tear on extruder barrels and screws, resulting in lower maintenance costs

2. Faster start-ups and reduced human resources

3. Approximately 20% reduction in energy requirements

Challenges encountered with pumps in blown film industrial lines:

1. throughput increases may vary

2. downstream limitations

3. instrumentation changes may have been optimized by using the right combination of cooling, screw design, and removal equipment

4. initial cost of pumps and ancillary equipment

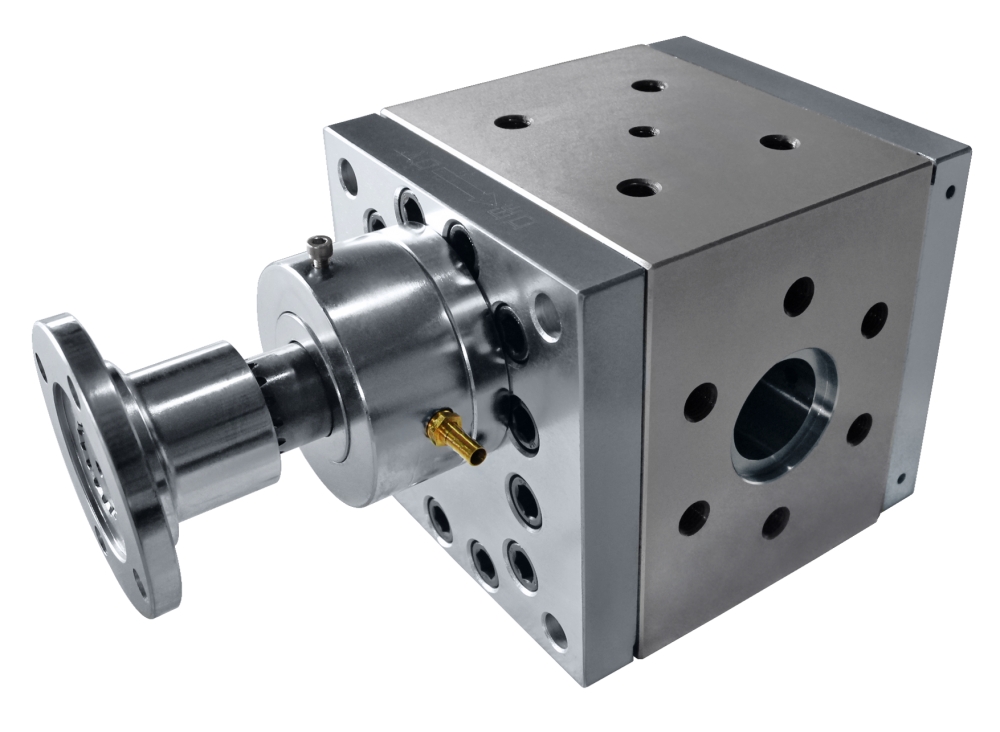

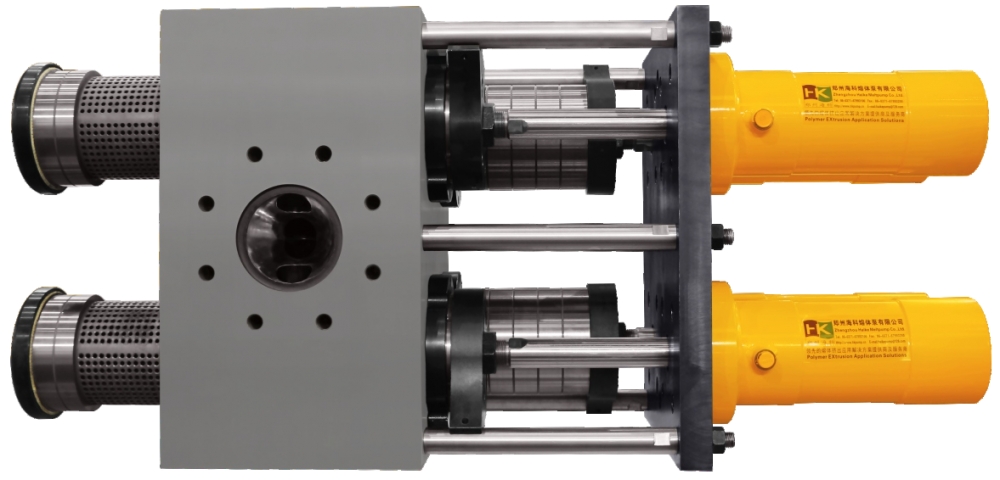

Heiko specializes in the manufacture of all types of melt pumps and screen changers.

Melt pump common faults and countermeasures

Functions and advantages of the hydraulic pelletising screen changer

Screen changer leakage phenomenon of different working conditions solutions

Melt Thermal Degradation in Relation to Melt Pump Structure

Melt booster pump jamming and end cap leakage

Features and technical advantages of melt-pumps for heat-sensitive materials

Overview of Hydraulic Screen Changer Technology

Structure and working principle of high temperature melt-pump

How do you change the screen on an automatic screen changer?

What factors does consider, choosing hydraulic screenchanger of PVC pelletizing