CANCEL

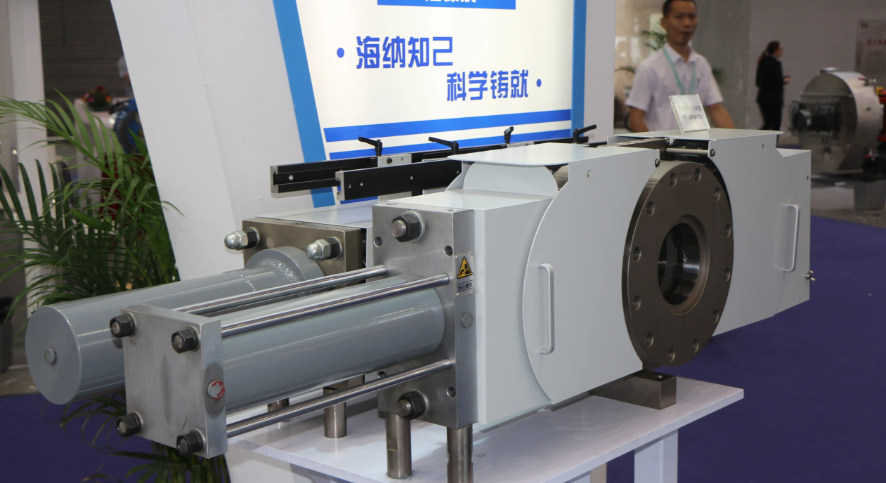

The core of the PVC regranulation plate screen changer (commonly known as a plate changer) features a single-plate, dual-station hydraulic drive system. Its straight-through flow path minimizes retention and enables rapid screen changes. Designed to accommodate the heat-sensitive nature and high impurity content of PVC regranulation material, it is suitable for extrusion pelletizing, profile extrusion, and pipe extrusion applications.

Core Principle and Structure

Working Principle: Hydraulically driven sliding plates enable dual-station screens to alternately engage the flow channel. Screen change time ≤ 2 seconds with minimal pressure fluctuation, allowing non-stop operation to reduce PVC degradation risks.

Core Components: Body (straight-through flow path, no dead zones) Slide plate (dual-station screen mounting position) Hydraulic system (drive and seal compensation) Heating/temperature control unit (160–200°C compatible) Sealing structure (compensated/pressure-activated, leak-proof and pressure-resistant).

Key Selection Parameters

Process Compatibility

Melt Parameters: Temperature 160–200°C, operating pressure ≤30MPa, pressure differential ≤20MPa.

Filter Specifications: 80–120 mesh (combination coarse + fine filtration), filter area matched to output (φ70–φ350mm).

Structure Selection

Prioritize single-plate dual-station hydraulic models (high cost-effectiveness, easy maintenance); for high output, opt for dual-plate quad-station models for more stable continuous filtration.

Flow Path: Straight-through design, avoiding right angles/dead corners to minimize residue buildup.

Installation & Interfaces

Flange connections matching extruder/mold diameters; reserved heating and hydraulic interfaces for integrated control.

Application Scenarios & Recommended Pairings

Suitable for: PVC regrind pelletizing, profile/pipe extrusion, sheet production, especially for small-to-medium production lines (≤1000kg/h).

Recommended Pairing: Use with a melt pump to stabilize pressure and flow, enhancing product uniformity and surface quality.

Material selection of melt pump

What materials can the melt pump transport?

Application areas of plastic extrusion melt pumps

Heiko Company had participated in the CHINAPLAS 2024.

Melt-Blown Dual-Column Non-Stop Hydraulic Screen Changer

plate screen changer for pvc regranulation

Reactor Melt Discharge Pump

Rubber Elastomer Melt Gear Pump

Core Structure of Melt Pumps

What is the maximum working pressure of a twin-shaft melt gear pump?